Top Tips for Effective Electric System Troubleshooting

Repairing electric systems needs a methodical method, based in a comprehensive understanding of electric principles and safety protocols. The nuances of efficient troubleshooting extend beyond plain technical understanding; understanding exactly how to record findings and focus on safety and security can significantly influence end results.

Understand the Fundamentals

Comprehending the basics of electrical systems is vital for reliable troubleshooting, as a solid foundation enables professionals to identify and fix issues extra successfully. A thorough grasp of electric principles, such as voltage, present, resistance, and power, is critical in recognizing the source of issues. Voltage is the electric potential distinction that drives existing via a circuit, while resistance opposes the circulation of present, impacting the total performance of the system.

Knowledge with circuit elements, consisting of resistors, capacitors, diodes, and switches, is likewise extremely important. Each component plays a distinct function in circuit habits and can impact efficiency when malfunctioning. Furthermore, comprehending collection and identical circuit arrangements is crucial, as these setups affect the distribution of voltage and present within the system.

In addition, knowledge of safety procedures is crucial. Technicians should be aware of potential risks, such as shock and short circuits, to execute safe troubleshooting methods. By grasping these fundamental ideas, service technicians boost their capacity to perform efficient diagnostics and repairs, inevitably leading to improved performance and integrity of electrical systems. This foundational knowledge is the foundation of effective troubleshooting undertakings.

Gather Necessary Devices

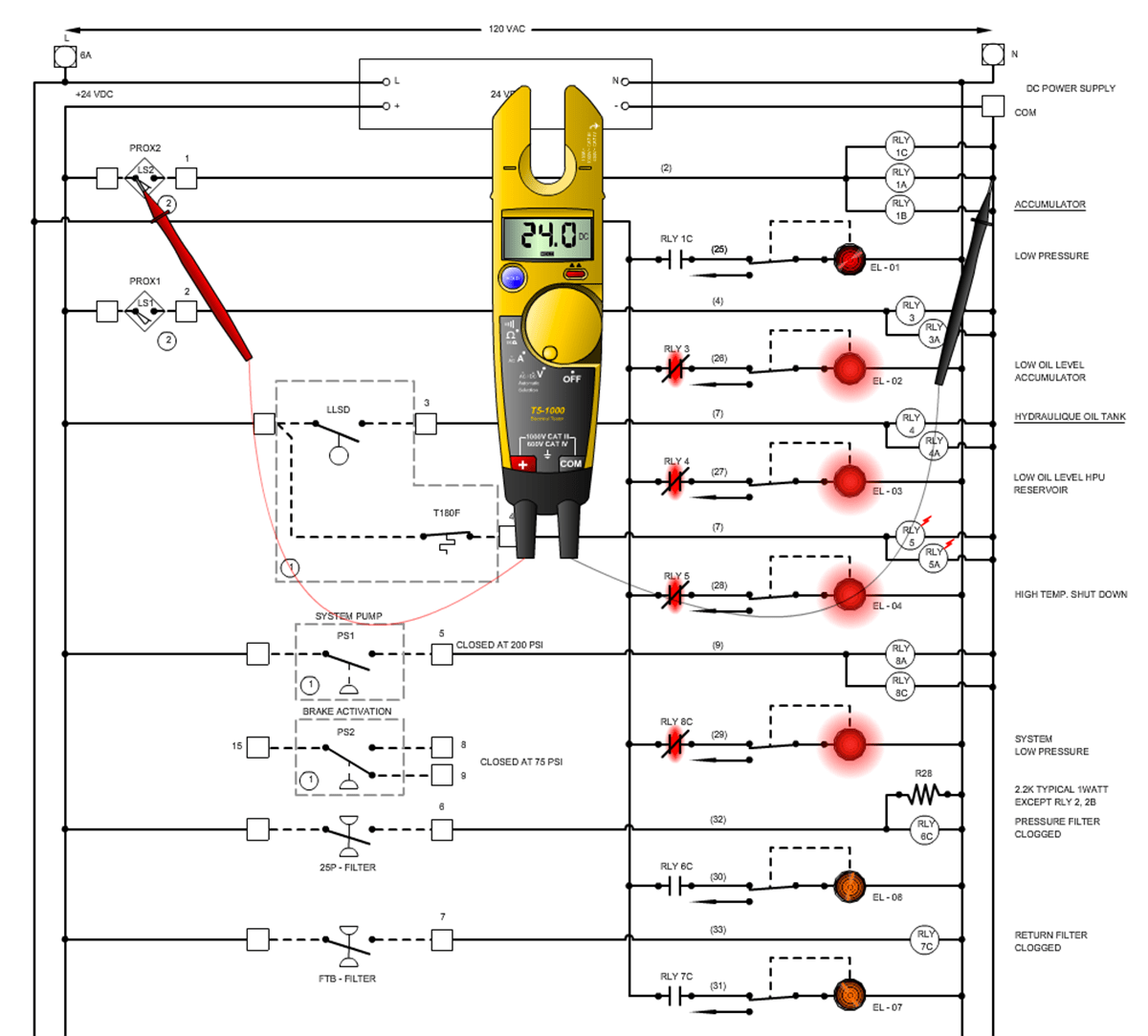

Reliable troubleshooting of electric systems calls for the right set of tools to identify and fix problems accurately. Important tools include a multimeter, which determines voltage, present, and resistance, permitting for exact analyses of electric parts.

Furthermore, insulated hand devices such as screwdrivers, pliers, and cord strippers are critical for safely controling electric links. It is likewise recommended to have a circuit tester handy to verify the visibility of voltage in outlets and wires. For even more complex systems, a thermal imaging camera can help detect overheating components, showing potential failings.

Adhere To an Organized Method

Having collected the suitable tools, the following action in repairing electric systems is to adhere to an organized method. A methodical strategy makes certain that service technicians can identify faults successfully and accurately, lessening downtime and stopping unnecessary fixings.

Begin by assessing the system's schematic layouts and specifications. Recognizing the design and functional criteria will certainly offer context for identifying issues. Next, isolate the trouble area by making use of a procedure of removal. This entails monitoring each part methodically, starting from the source of power and working in the direction of the tons.

Make use of testing tools, such you can try this out as multimeters and oscilloscopes, to collect unbiased information concerning voltage, existing, and resistance at numerous factors within the system. This empirical proof will guide your troubleshooting efforts and assist to verify or eliminate possible sources of failing.

Additionally, consider ecological factors that may affect the system's efficiency, such as temperature variations or moisture access. A detailed examination of circuitry, links, and components will certainly guarantee that all opportunities are made up.

File Your Findings

Comprehensive documentation is crucial in the fixing procedure of electric systems. This method not just aids in comprehending the origin reason of the trouble however likewise offers as a reference for future fixing initiatives.

Furthermore, keeping a log of components replaced or repair services carried out is vital. This information supports supply monitoring and can assist evaluate the longevity and integrity of certain elements.

Ultimately, the documentation process should be extensive yet succinct, allowing easy access and review - electrical system troubleshooting. By prioritizing detailed documentation, specialists can develop an important data base that not just aids in current troubleshooting however likewise empowers future maintenance initiatives, thus boosting overall system reliability

Prioritize Precaution

Identifying the fundamental see here dangers connected with electric systems is important for guaranteeing security during troubleshooting. Electrical shock, burns, and equipment damages are simply a few of the potential hazards that service technicians deal with. Focusing on safety and security steps is not only a lawful obligation however additionally a moral important that safeguards both the specialist and the surrounding environment.

Before starting any type of troubleshooting task, technicians need to wear proper individual safety tools (PPE), including protected handwear covers, safety and security glasses, and flame-resistant clothes. Making sure that the work area is completely dry and devoid of mess can significantly lower the risk of crashes. It is important to de-energize circuits prior to starting any type of work, validating that they are not live via the usage of a multimeter or voltage tester.

Establishing clear interaction procedures with employee is additionally vital; this guarantees that everybody understands potential risks and the standing of the electrical system being serviced. Last but not least, having an emergency action strategy in place can confirm important in the occasion of an event. By focusing on precaution, technicians can properly mitigate risks and cultivate a safer workplace.

Verdict

Reliable electric system repairing relies on a thorough understanding of essential concepts and a systematic strategy. Prioritizing security steps makes sure the wellness of individuals included and the stability of the electric system.